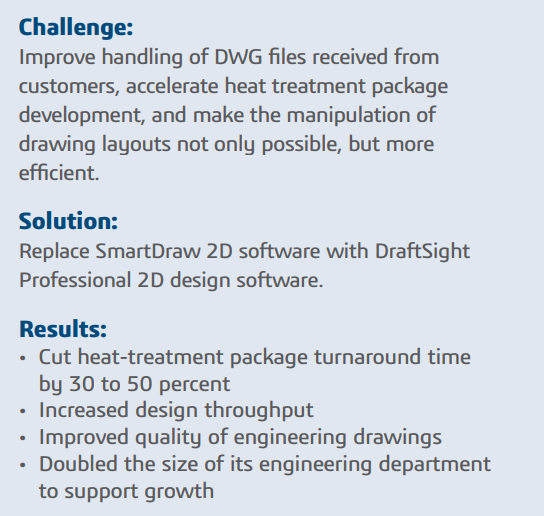

Until 2018, Superheat utilized 2D diagramming software to create layouts for its heat-treatment quality packages and SOLIDWORKS® 3D design software to develop more specialized and sophisticated heat-treatment designs. However, the 2D software that Superheat used had limited capabilities, and its inability to read DWG files (the most common customer format for components requiring heat treatment) and manipulate engineering drawing layers prompted the company to evaluate other 2D design solutions, according to Engineering Tech Supervisor Brent Walton.

We create our drawings in such a way that our field technicians know how to wrap vessels, components, or piping to meet code requirements for heat treatment, and our drawings include much of our valuable knowledge, expertise, and intellectual property (IP),” Walton explains. “In addition to reading in customer DWG files, we needed the capability to manipulate drawing layers, which allows us to then remove our sensitive IP from drawings that we deliver to our customers or charge them if clients choose to purchase drawings containing all layers as part of their heat-treatment solution.” Because Superheat uses SOLIDWORKS 3D design software to complete special projects, it became aware of DraftSight® 2D design solutions and immediately began using DraftSight for opening DWG files from customers. The company then purchased many DraftSight Professional licenses to support the manipulation of drawing layers. Superheat chose DraftSight Professional software because it is familiar to and easy-to-use by engineers with experience using AutoCAD® software, is a fraction of the cost of AutoCAD, and is fully compatible with the SOLIDWORKS 3D design system.

Click here to read the case study on our Quality Package Development with DraftSight Professional!