Introduction

Resting on laurels and using traditional equipment and procedures are commonplace among oil and gas contractors. Operating expenses associated with research and development coupled with a reluctance towards change generally reduces the time and money spent on innovation. As a result of poor third-party service offerings, facility owners are generally subjected to inherited liability. At no fault of their own, capital, turnaround, and maintenance projects commonly surpassing budget, extending schedule, and expose their workforce to unnecessary safety risks. So, when PBF Energy’s Martinez refinery, producer of 157,00 barrels-per-day and one of the most complex refineries in the United States (Nelson Complexity Index of 16.1), put out an RFQ for on-site heat treatment applications for two coke drums during their 2021 DCU Maintenance Pit Stop Outage, Superheat knew we needed to provide one of our latest innovations to make the project an outstanding success.

With a reinvention of the traditional flexible ceramic pad heater using the integration of magnets the Superheat MagneMat™ was born. Bobby Wilkes, Field Maintenance Supervisor and key principle for PBF during the outage said, “Superheat used their new magnetic heaters, they were a huge success, and I was really impressed with the maneuverability”.

Scope & Schedule

Cracks in coke drums are nothing new due to the nature of the temperatures, cyclic service, and stresses involved. However, the efficiency in which the preheating application is set up in preparation for weld repair can have critical impacts on the overall schedule and cost of the project.

PBF Energy’s Martinez Refinery required 35 preheat applications to support welding in accordance with ASME Section VIII Div 1 on two coke drums. The cumulative scope of the weld repair amounted to a total of 856.5 linear feet – no small task as each independent repair requires a custom setup with its own unique challenges.

The conventional approach to preheat set up for vertical weld repairs on coke drums requires a multitude of procedural steps, one being the need to secure flexible ceramic heating elements using a pin gun in collaboration with the appropriate banding techniques. This critical phase ensures the heating elements (heaters) do not shift during the heat treatment ramping phase and/or during the welding process. If said shifts did occur, this could affect the ability of the HAZ (heat affected zone) and the base material to reach and maintain adequate preheat temperatures outlined in the qualified weld procedure. This potential non-conformance may require an improvement to the setup prior to welding, or in extreme cases a cut out if the weld didn’t receive proper heat distributions during welding. However, the impact on schedule and thus cost associated with the pinning process extends far beyond the heat treatment contractor as pre-vessel mapping, installation, and removal of pins requires pre/post grinding, NDE (nondestructive test), and extensive quality management measures.

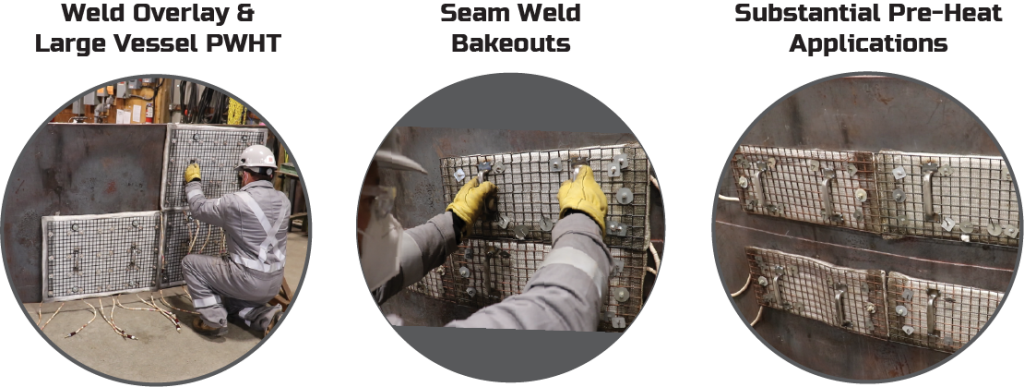

The Superheat SmartWay™ Solution Integrates New MagneMat Heating Element

Over the course of several years Superheat has invested significant research and development into magnet technology that will forever change the design and installation methods of flexible ceramic heating pads on large vessels and big bore piping. Where others have failed Superheat has put a priority on procurement research and testing of magnets in which their electromagnetic field are minimally affected by standard Preheat and PWHT temperature parameters. The integration of these magnets into the traditional heater has created the new Superheat MagneMat™ which eliminates the requirement for pins during the heater setup process entirely. The fallout of this advancement has substantial cost and schedule savings to end users.

To see the Superheat MagneMat™ in action, please watch on the video below.

When considering the industry average setup for preheat application as it applied to PBF’s two coke drum repair scope it was calculated that the Superheat MagneMats™ alleviated the need to attach, grind off, and inspect 540 pin locations (90 H-7 heaters x typically 6 pins/heater = 540, also not accounted for pins generally used to secure insulation). The trickle-down effect of this revolutionary change to heater set up not only reduced schedule attributed to heat treatment by up to 50% but cut overall costs related to NDE of each pin location.

When not used for heat treatment setup the Superheat MagneMat™’s played a cross-functional roll in welder safety during through wall repairs on the interior drum. As preheat was only required on the exterior of the drum internal weld areas were bare to the exposure of local heat. This made it difficult for welders to steady themselves against the structure to produce high-quality welds and posed a significant burn risk. Superheat MagneMat™’s with their ease of installation and unmatched maneuverability gave welders the opportunity to efficiently place mats as protection in areas where they needed it most. Additionally, by simply providing this tool to welders Superheat didn’t interfere with their progress or working environments and is yet another example where grinding, pins, and NDE were not necessary on the interior of the drum.

Jobsite footprint and the productivity of on-site labor are always critical factors when evaluating project efficiency. Superheat strives to do more with less and outfitted the Martinez refinery with five of their highest zone capacity consoles – the Superheat SmartPoint™ CN24. At a compact and portable size of just 45’’H x 25’’W x 25”D the SmartPoint™ CN24 outputs a staggering 24 Control Zones and a mammoth 48 total thermocouple inputs. A capacity unmatched by the nearest provider, enabling Superheat to do more work and occupy less room on the jobsite. However, production can never overlook safety. The CN24 is the only heat treatment console engineered and certified to UL # 508A/CSA # C22 No.14-10 Standards and coupled with the integration of our Superheat SmartPak™, creates the industry’s only safety lock out capability directly at the weld location.

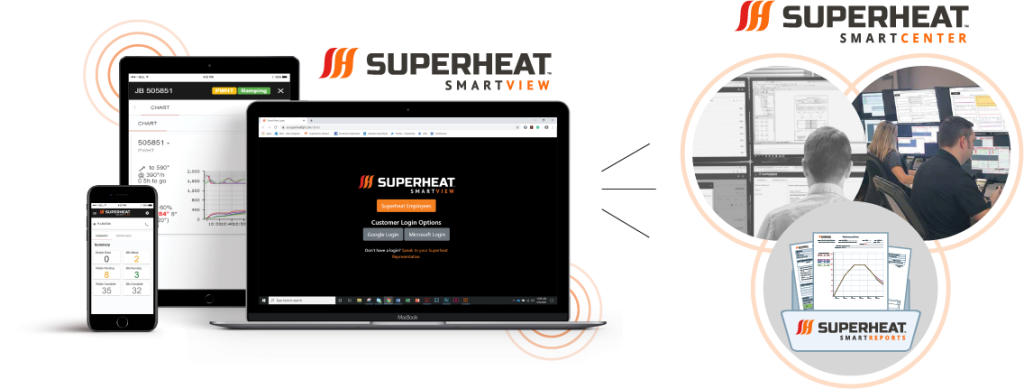

On-site tasks are only half the story as Superheat’s patented process is dependent on communication technology and innovative software solutions that make the Superheat SmartCenter™ the knowledge and control hub of the heat treatment process. The Superheat SmartCenter™ and its technical

engineering group provides the knowledge and design expertise to field staff, outlining the optimal setup and tear down of heat treatment configurations. Once the setup of the preheat configuration at the Martinez Refinery was completed, highly trained control room operators in the Superheat SmartCenter™ then control Superheat SmartPoint™ consoles via a patented remote-operation process. While the Superheat SmartCenter™ performs critical quality check aspects, Superheat Technicians & Project Site Management can remain focused on the safe and proficiency set-up and tear-down of welds. This ensures on-site labor forces are optimized, and heat cycle quality is maximized. The time and cost saving because of field and Superheat SmartCenter™ staff working simultaneously has far-reaching impacts on the overall success of this project.

Superheat SmartView™, a component within our overall patented solution, provided one source of the truth to PBF regarding overall project data. More specifically, SmartView™ provides quantitative heat treatment information in real-time via any device. From the palm of their hands, clients can now view live critical information from the SmartCenter™ pertaining to Weld Running Status, Live Heat Treatment Charts, and a multitude of other features.

Results

When PBF conducted its 2021 DCU Pit Stop Outage Look Back meeting and reviewed the strengths and opportunity outcomes from the project, it was clear this outage was nothing short of an excellent success.

Two key performance metrics listed during the lookback discussion were schedule and budget, the outcomes taken from the meeting summary notes can be found below:

Schedule: A Day Early

Budget: Significantly under budget.

Two areas in which the use of MagneMats™ had a significant impact.

Field Maintenance Supervisor and main overseer on the project, Bobby Wilkes, also took the time during our Superheat customer satisfaction survey to say “Jim Valentino (Superheat Site Manager) was awesome, very transparent, and a good leader”. He also proceeded to rank all satisfaction categories and overall performance a score of “Superior”.

Have questions or interested in utilizing MagneMat™ technology on your next project? Send us a message through our Contact Us page form today!

Superheat began in 2000 and was founded on the principle that innovation and technology advancements can produce a safer, more cost-effective, quality driven way to provide high-quality on-site heat treatment services. We remain the world’s premier on-site heat treatment service provider and continue to build a long-term sustainable growth company providing services to the industrial energy and oil markets.

For any media-related questions or inquiries please email marketing@superheatfgh.com or call 1.888.508.3226