Introduction:

Ensuring safety remains paramount in both manufacturing and operational processes is a defining characteristic for on-site heat treatment providers. Within the dynamic realm of industrial on-site heat treatment, strict adherence to safety measures, procedures, and technological advancements is not merely a choice but an imperative.

At Superheat, safety transcends being a mere priority – it stands as a foundational pillar of our company ethos. We take pride in not only meeting but surpassing safety standards. With an unwavering commitment spanning 24 years, we have achieved an impressive record of five years with zero recordable injuries. This accomplishment not only underscores our dedication to the well-being of our workforce and the establishment of a robust safety culture but also highlights our ongoing investment in R&D engineering. We take great pride in seamlessly integrating innovative safety features directly into our products manufacturing roadmap.

Superheat’s Cutting-Edge QR Code Safety Portal and Dynamic SWAT Program:

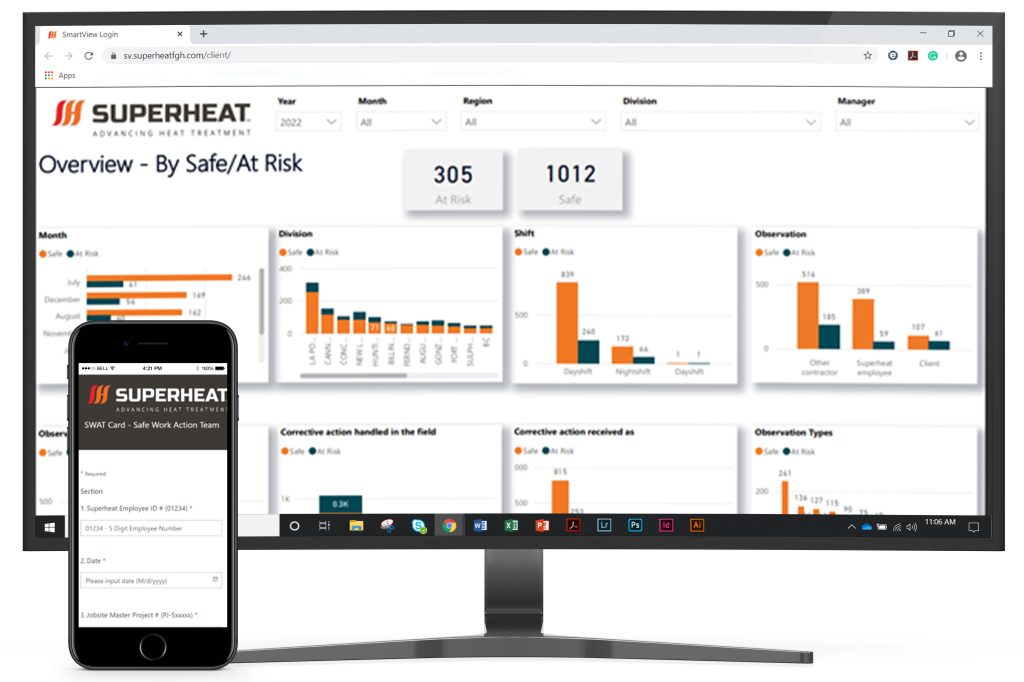

Embracing the paperless revolution is not just a stride towards sustainability; it’s a dynamic enhancement in how Superheat team members can seamlessly submit and access real-time safety information. As part of our commitment to being the epitome of “Better.Safer.Faster” on-site heat treatment providers, we’ve transitioned from conventional paper-based safety documentation to an innovative QR code-accessible digital safety portal. The portal encompasses a comprehensive array of features, ranging from safety procedure documentation, incident reports, and regional safety contact information to SWAT (Safe Work Action Team) observation submissions and, most notably, the addition of vehicle inspection sheets.

Providing convenient access to vehicle inspection sheets for our staff, anytime and anywhere, has yielded remarkable results. In 2023 alone, we observed a threefold increase in inspections, enabling us to proactively identify and rectify numerous vehicle issues before granting them permission for use.

The dynamic SWAT card submittal process encourages and rewards employees for continuously engaging in observing their surroundings/colleagues during daily work tasks for safety risks. This observational data is documented using digitally submitted SWAT card forms through the safety QR code portal. To foster collaboration and enhance safety practices, regional teams convene monthly to review the submissions, share insights, explore emerging trends, and offer recommendations for refining the safety process and addressing any issues that may arise.

The Primary Objectives of the SWAT Program are:

- Excel in safety – be the best in the industry.

- Recognize and reinforce safe behaviors.

- Recognize and eliminate “At Risk” behaviors with immediate intervention.

- Create a safety culture focused on improving behaviors before an incident or accident occurs.

- Utilize the SWAT data to develop injury prevention initiatives and reward successes.

- Incorporate trust among coworkers to keep watch on one another without questions or reprimand.

- Promote ownership of the process and active employee involvement. Field Technicians at all levels are encouraged to promote

the identification of at-risk behaviors so that they can be eliminated from the work areas through feedback and intervention.

Monthly individual digital submissions are tracked, and participants are recognized through a tiered system: Level 3 (Participant – under 4 SWAT cards), Level 2 (Silver User 4 SWAT cards), and Level 1 (Smart User – 5 or more SWAT cards). Submitters from each category enter a pool, from which SWAT members select two quarterly winners. Winners then can choose awards, such as family-impactful gift cards. The eight quarterly winners become eligible for the annual award, determined by SWAT members. Recognition extends through the company safety newsletter, website, and social media platforms.

In 2023, there was a notable 57% increase in SWAT card submissions, underscoring the effectiveness of our digital safety innovation. This advancement empowers employees to promptly report events that might otherwise go unnoticed due to the cumbersome process of completing and managing physical forms. Distinguishing ourselves from others in the on-site heat treatment and related industries, we wholeheartedly embody the “Stop Work Authority” principle. Our commitment is evident as we encourage employees to invoke this authority whenever they perceive a situation as unsafe, fostering a culture where they face no negative repercussions. The authority applies to all actively involved parties, and after a thorough safety evaluation, corrective actions are implemented to ensure a secure work environment. Instances of invoking the Stop Work Authority can be submitted as SWAT cards, providing an additional incentive for our staff to engage in our safety initiatives actively.

Superheat SmartView™, our comprehensive project management app, grants instant access to various safety resources. This includes site-specific safety protocols, lessons learned, PPE requirements, PAR (personal accountability rosters) management, and approved driver lists. With this interactive platform, site management has the tools and knowledge at their fingertips to ensure a secure working environment for field team members. Moreover, SmartView’s document upload feature allows site-level Managers to share daily tailgates and exchange critical safety information easily. This data undergoes regional and national level audits during KPI meetings, facilitating a proactive approach to collecting, distributing, and analyzing safety data through digital innovation. The outcome significantly impacts our ability to uphold the highest industry safety standards, as reflected in key metrics such as EMR, TRIR, and LTI (see end of article).

Elevating Safety Standards with Superheat’s SmartCenter™, SmartPak™, and SmartCard™ Innovations:

At Superheat, we stand alone as the world’s exclusive company dedicated to the complete remote operation of on-site equipment through our centralized Superheat SmartCenter™. Utilizing patented technology and equipment advancements, our on-site heat treatment service ensures that 100% of equipment and heat cycles are controlled remotely. This groundbreaking approach reduces the required footprint on job sites by up to 40%, enhancing safety by minimizing field staff exposure to potentially hazardous areas.

In 2023, we reaffirmed our commitment to remote monitoring with a comprehensive expansion of SmartCenters in Canada, the United States, and the United Kingdom. This involved expanding pod locations to align with market share growth, ensuring our operators are redundant and can sustain ever-growing demand.

Moreover, the Superheat SmartPak™ stands as the industry’s sole equipment offering safety lock-out capability directly at the component location, mitigating the risk of electric shock to field personnel. Upon completing standardized training, Technicians receive a personalized Superheat SmartCard™ that, when swiped at the Superheat SmartPak™, instantly locks out power to the weld. This allows individuals to control safety directly and eliminates the need to leave the work area to isolate power, even when equipment consoles are located at a distance. The card swipe signals to our panel operators that the heating process can safely commence, confirming the weld area’s safety condition.

Our Safety Breakthrough with the Superheat MagneMat™:

Superheat has revolutionized the conventional approach to on-site heat treatment, particularly in the oil and gas sector. Unlike the prevalent tendency to stick to traditional methods due to cost concerns and resistance to change, Superheat has invested in magnet technology. This innovation has transformed the design and installation methods of flexible ceramic heating pads, resulting in the development of the Superheat MagneMat™.

The procurement priority on magnets with minimal electromagnetic field impact under standard temperature parameters has eliminated the need for pins in preheat and PWHT processes. The Superheat MagneMat™ streamlines the setup process, eradicating risk events like pre-vessel mapping, pin installation/removal, pre/post grinding, NDE, and extensive quality management measures. This groundbreaking solution not only upholds elevated standards of quality and efficiency but also dramatically reduces risks associated with on-site heat treatment and benefits all parties involved in the life of a weld. To see the MagneMat in action, check out our video to the left.

Conclusion:

In conclusion, Superheat’s 24-year commitment to safety is deeply embedded in our company ethos, reflected in our exemplary record of five years with zero recordable injuries. No matter how subtle, every incremental innovation enhances the safety of our team’s working environment and the consequential metrics we achieve. The unwavering commitment of each Superheat Team member has been pivotal in elevating safety as our foremost priority every single day.

Our dedication surpasses industry standards, underscored by the integration of innovative safety features and a robust safety culture. Technologies like the QR code-accessible digital safety portal, the dynamic SWAT program, and the Superheat SmartView™ app showcase our proactive approach, evidenced by a notable 57% increase in SWAT card submissions in 2023.

Our commitment extends to revolutionary advancements such as the Superheat MagneMat™ and the exclusive remote operation capabilities through SmartCenter, SmartPak, and SmartCard innovations. These innovations reduce job site footprints by up to 40% and minimize field staff exposure to hazards. The recent SmartCenter™ rebuilds and continuous technology investments reinforce our dedication to leading the industry in safety and efficiency. Superheat’s holistic approach, integrating cutting-edge technologies, robust safety programs, and proactive measures, positions us as a trailblazer committed to creating the safest working environments in the on-site heat treatment industry.

United States Safety Statistics:

| Variable | 2021 | 2022 | 2023 | 3 Year Avg. |

|---|---|---|---|---|

| Experience Modification Rate (EMR) | 0.56 | 0.59 | 0.61 | 0.58 |

| Total Recordable Incident Rate (TRIR) | 0 | 0 | 0 | 0 |

| Loss Time Injury (LTI) | 0 | 0 | 0 | 0 |

Canada Safety Statistics:

| Variable | 2021 | 2022 | 2023 | 3 Year Avg. |

|---|---|---|---|---|

| Total Recordable Incident Rate (TRIR) | 0 | 0 | 0 | 0 |

| Loss Time Injury (LTI) | 0 | 0 | 0 | 0 |

United Kingdom Safety Statistics:

| Variable | 2021 | 2022 | 2023 | 3 Year Avg. |

|---|---|---|---|---|

| Date Away Restricted or Transferred (DART) | 0 | 0 | 0 | 0 |

| Reporting of Injuries, Diseases & Dangerous Occurrences Regulations (RIDDOR) | 0 | 0 | 0 | 0 |