Superheat Achieves Unparalleled Efficiency, Safety, and Cost Savings

Recently, we completed a significant new construction project at a large-scale LNG facility near Western Canada’s Gitnadoiks River Provincial Park, showcasing our commitment to innovation, safety, and client success. Over 23 months, our team delivered exceptional results that exceeded expectations.

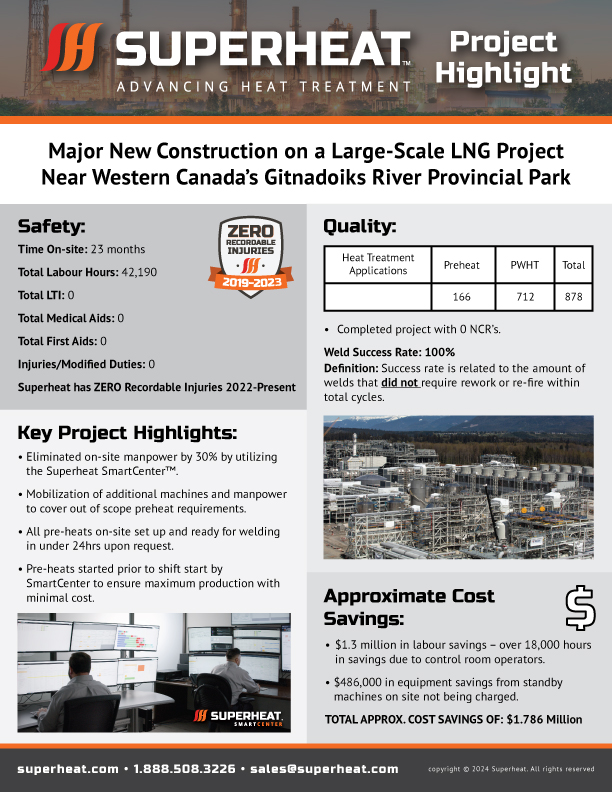

Safety Performance: Zero Recordable Injuries

At Superheat, safety is non-negotiable, and this project was no exception. Our team completed 42,190 labour hours without a single recordable injury, medical aid, or first aid incident. With zero lost time injuries (LTI) and no modified duties required, this project underscores our focus on maintaining a safe work environment.

Key Safety Stats:

- Time on-site: 23 months

- Labour hours: 42,190

- Total recordable injuries: 0

- Modified duties: 0

Quality Results: 100% Weld Success Rate

During the project, Superheat completed 878 heat treatment applications (166 preheats and 712 post weld heat treatments), achieving a 100% weld success rate. This means every weld we treated met stringent quality standards without requiring rework or re-fire, a testament to our precision and expertise.

Innovation and Efficiency: Superheat SmartCenter™

Our remotely operated Superheat SmartCenter™ was pivotal in driving efficiency throughout the project. By utilizing this innovative technology, we reduced on-site manpower by 30%, enabling a leaner workforce without compromising productivity. Here’s how we made it happen:

- Preheats were set up and ready for welding within 24 hours upon request.

- Preheats were started before shift changes to maximize production and minimize costs.

- Mobilization of additional machines and manpower allowed us to handle out-of-scope preheat requirements seamlessly.

Cost Savings: $1.786 Million

By integrating cutting-edge technology and operational efficiency, we delivered significant cost savings for the client:

- Labour Savings: $1.3 million was saved through reduced on-site manpower, totaling over 18,000 hours of savings.

- Equipment Savings: $486,000 saved by avoiding standby charges for machines on-site.

- Total Approximate Savings: $1.786 million

The Bottom Line:

This project highlights Superheat’s ability to deliver unparalleled safety, quality, and efficiency while driving significant cost savings for our clients. We’re proud to have been a trusted partner in this large-scale LNG project, and we look forward to continuing to push the boundaries of innovation in on-site heat treatment.

To learn more about how Superheat can help optimize your next venture, visit our SmartWay page today.