Induction vs Resistance Heating – Blog Summary:

- Choosing the Right Solution: Both on-site electrical resistance and induction heat treatment systems are highly effective and complementary, with each suited to different project requirements. Superheat can guide you in selecting the most efficient and appropriate method for your specific application.

- Induction On-site Heat Treatment: Induction heating delivers fast, localized heat, making it ideal for repetitive applications, quick preheats, and simple geometries. It improves productivity, keeps the surrounding workspace cooler, and adapts to various shapes and steel projects.

- Electrical Resistance On-site Heat Treatment: Electrical resistance heating provides precise, uniform, and repeatable temperature control, ideal for heavy-wall components, confined spaces, and applications requiring strict thermal gradient control. It is versatile across materials and thicknesses, supporting multiple heat treatment applications simultaneously.

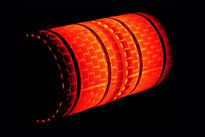

Induction On-site Heat Treatment

Advantages:

- Speed: Rapid localized heating, reducing cycle times and improving overall productivity (where code permits)

- Workspace Benefits: The surrounding area stays cooler with heat concentrated only within the workpiece, improving welder efficiency

- Rotating Components: Ideal for repetitive or rotating cylindrical parts in fabrication facilities

- Flexible & Adaptable: Coils can be adapted to a variety of geometries, typically requiring fewer field connections

- Complementary to Resistance Heating: Enhances productivity in preheating and simple geometry applications

- Minimizes Risk: No open flames or combustion, generates limited noise, no dust or smoke during operation

Limitations:

- Multiple welds can be heated simultaneously only when the diameter, thickness, and material are consistent

- Localized heating provides less zone control over complex gradient code parameters

- PWHT is dependent on specific materials or metallurgical requirements

- Higher electrical outputs directly at the weld (35kW), water-cooled coils present potential hazards if damaged

Optimized Applications:

- Quick preheats or PWHT. Adapts to a wide range of applications and heating processes, effective on most steel projects of varying shapes and sizes.

- Fabrication facilities with rotating parts or heavy-wall piping

- Jobs where speed improves productivity without compromising quality

Electrical Resistance On-site Heat Treatment

Advantages:

- Accuracy & Repeatability: Used in over 90% of field heat treatment applications; reliable results across multiple welds or components

- Full Gradient Control: Heat band and soak band provide 360° coverage and precise zone management

- Uniform Temperature: Essential for large heavy-wall components and advanced chrome alloys

- Safety & Efficiency: Low operating voltage (~80V -45 Amp 3.6 kW per element), minimally exposed cabling, energy-efficient

- Versatile Applications: Effective for varying material thicknesses, dissimilar metals, confined spaces, and heat sinks

Limitations:

- Slower ramp rates compared to induction for preheating tasks (where code permits)

- Potential heater loss during extended operations or high-duty cycles

Optimized Applications:

- Post weld heat treatment (PWHT), preheat (PH), and bakeout

- Heavy-wall piping and vessels

- Confined or congested work environments

- Components requiring precise temperature gradients

- A single machine can accommodate multiple welds across varying material thicknesses, dissimilar metals, and varying cycle parameters

Induction vs Resistance Heating Comparison Chart:

| Feature/Attribute | Induction Heating | Electrical Resistance Heating |

|---|---|---|

| Accuracy & Repeatability | Moderate; gradient zone control less precise | High; used in over 90% of field applications |

| Temperature Control | Excels at localized heating | Full gradient control with heat and soak bands; uniform zone control |

| Speed (Code Permitting) | Rapid; quick preheats improve productivity | Steady and controlled |

| Versatility | Flexible coil designs, fewer field connections, excels at consistent and repetitive work | Handles varying thicknesses, heat sinks, and complex layouts |

| Workspace Impact | The surrounding area remains cooler | Heat radiates the surrounding area and components |

Superheat SmartLink™ + Miller ProHeat™ 35

(Regardless of cable length)

| Number of 6″ STD Wall Thickness Weld Operated at One Time |

|---|

| Preheat: QTY 2 OR PWHT: QTY 2 |

| Number of 12″ STD Wall Thickness Weld Operated at One Time |

|---|

| Preheat: QTY 2 OR PWHT: QTY 2 |

| Number of 20″ STD Wall Thickness Weld Operated at One Time |

|---|

| Preheat: QTY 2 OR PWHT: QTY 2 |

| Number of 24″ STD Wall Thickness Weld Operated at One Time |

|---|

| Preheat: QTY 2 OR PWHT: QTY 2 |

Superheat SmartPoint™ CN24

(24 heaters individually controlled)

| Number of 6″ STD Wall Thickness Weld Operated at One Time |

|---|

| Preheat: QTY 8 OR PWHT: QTY 24 |

| Number of 12″ STD Wall Thickness Weld Operated at One Time |

|---|

| Preheat: QTY 4 OR PWHT: QTY 4 |

| Number of 20″ STD Wall Thickness Weld Operated at One Time |

|---|

| Preheat: QTY 4 OR PWHT: QTY 2 |

| Number of 24″ STD Wall Thickness Weld Operated at One Time |

|---|

| Preheat: QTY 4 OR PWHT: QTY 2 |

If you’re still deciding between induction vs resistance heating, or want to apply either method to your next heat treatment project, send us a message through our Contact Us form, and a Regional Representative will reach out promptly to help you determine the best on-site heat treatment solution.