Industries We Work With &

Onsite Stress Relieving Services

Industries We Work With

Our engineering library pertaining to onsite stress relieving services and in-depth quality program knows each facility contains unique units, components, and materials. These varying conditions are governed by strict codes, standards, and procedural requirements in which we are well versed. You can trust your project is in the hands of the most advanced company in industrial onsite heat treatment.

Onsite Stress Relieving Services

Our singular focus is onsite stress relieving services. Our experience and technical knowledge are unmatched, ensuring your job gets done right the first time. Click the icons to learn more about each service.

Our Onsite Stress Relieving Case Studies

Not all industrial heat treatment projects are created equally. Get up-to-date industry news and see why we’re the market leader in efficiency, safety, and reliability.

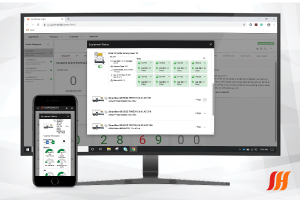

📢 In Partnership with Miller Electric, We Bring You an Enhanced Induction Rental Experience

We have leveraged our combined knowledge and technology to amplify the usability, digital quality management, and field-level support of your rented Miller ProHeat™ 35 induction heating consoles.